- Home

- Custom Made

- Applied Technique

Our products mainly manufactured from the three technologies below: intelligent anchor, hot melt recoverable technology and compressive stress-dispersive technology.

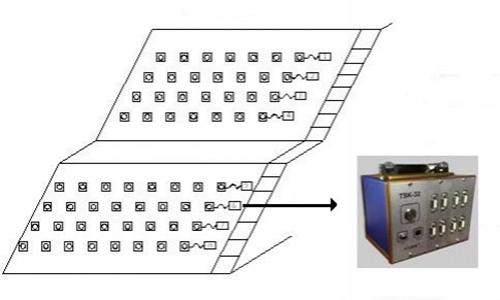

① Force-measuring components included

② Data transmission by the traverse

Slope condition and information collector using the intelligent anchor

Principle

Intelligent anchor are made by incorporating the strain gauge inside the anchor. As such, data are transmitted from the strain gauge to the terminal equipment in the office or the like via wired or wireless mode. This allows real-time monitoring and remote visualization on the bearing capacity.

Solved problems

Our intelligent anchor solves problems including inaccuracy of force measurement, failing to maintain the long-term stability of the force measuring equipment, unable to use it on large scale due to high cost and so on. The strain gauge is located at the end of anchoring section and wrapped with filler. As compared to the other anchors used in measuring stress, this has realized the dispersion of the internal stress in the meantime monitoring the internal force in each steel strand of respective anchor. Besides, this allows analyzing of the distribution of bearing capacity between each unit anchor according to the measuring results. Our strain gauge is designed ingeniously with waterproof property, resulting the force measurement of the anchor to be more accurate and long lasting. Today, this kind of intelligent anchor can be manufactured in one go at the factory.

Advantages

1) Realization of real time monitoring at the bearing capacity of the anchor during the work, avoiding fraud in anchor during the production process.

2) Accuracy greater than 95%

3) It can be used for permanent reinforcement as it has high corrosion resistance.

4) Suitable for use in temporary reinforcement projects such as foundation pits or slopes

| Product \ Influencing factor | Intelligent anchor | Conventional dynamometer |

| Monitoring accuracy | Each strand in the anchor | Whole anchor |

| Timeliness | Real-time measurement | Effective between 1-2years |

| Coverage | All strands of all anchor | 3%-10% ratio |

| Stability | High | High |

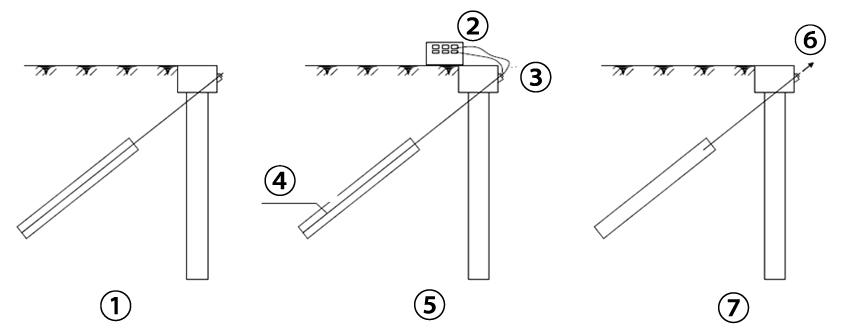

① Support stage;

② Transformer;

③ Electric heating;

④ Hot melt unlock;

⑤ Hot melt unlock stage;

⑥ Dismantle

⑦ Dismantling and recovering stage

Principle

The hot melt removable technology refers to the use of hot melting method to conduct removing and recovering of the anchor when it is not needed anymore. It is applicable to temporary structures such as slopes, foundation pits or permanent structures including counteracting uplift forces structures. The application of this technology improves the reliability of the anchor and allows it to be environmental friendly.

| Product \ Influencing factor | Hot melt removable strand anchor | Conventional removable strand anchor |

| Efficiency coefficient (Safety factor) | ≥90% | 50%~80% |

| Lifetime | Effective for 5 years | Effective between 1-2 years |

| Length | Electrical transmission, no influences | Difficult to unlock with distance longer than 20m |

| Stability | Mild impact | Slurry leakage easily occurred inside the pipe during construction. It is difficult to unlock. |

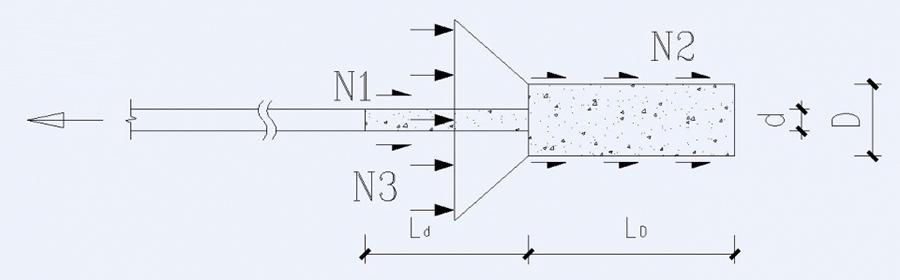

Principle

Compressive stress-dispersive technology is a new anchor construction technology which implements the modified high pressure rotary spray and stress-dispersive to develop a new anchor structure and construction method. The anchoring section of the anchor rod is about 2 to 3 meters long and has diameter between 0.6 to 0.8 meters. The inner part of the underreamed anchoring section and the bearing plate is uniformly distributed. The anchor rod provides the pull-out force depends on the anchorage section and the end-bearing capacity of the soil body. This advantage has effectively increased the pull-out force of the anchor rod installed in the cohesive soil and sandy soil as well as improving the construction efficiency and quality. It has been applied in many projects in China and with this technology, project cost can be reduced and the work efficiency can be increased greatly.

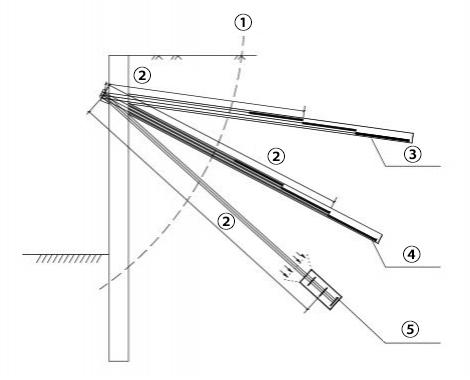

① Slip surface;

② Average length of unbonded segments;

③ Pulling force dispersion type;

④ Stress dispersion type;

⑤ Prestressed dispersion type

Advantages

① Reasonable structure

Ordinary tension-typed anchor first grouts the anchor end with cement mortar and the tensile force of the anchor is then transmitted to the cement mortar through the surrounding grip force of the anchor. Later, the force is transmitted to the reinforcement zone of the stable ground layer through the anchorage of the cement mortar and the frictional force between the ground layer. Tensile force is gradually transmitted from front to back to the anchoring soil. Shear stress along the rod has uneven distribution due to its centralized stress.

Compressive stress-dispersive anchor belongs to the pressure type anchor category. It uses unbonded steel strands to separate the reinforcement from the grout. The tensile stress of the rod is first transmitted to the grouting with the compressive stress which applied at the bottom end of the grouting by the bearing plate. Next, the force is transmitted to the stable soil body of the anchoring area through the end resistance between the bottom grouting body and the surrounding soil body.

Overall, the end bearing capacity of the soil and anchorage section provide a total of 60% to 70% of the pull-out force from the anchor while the side friction of the anchorage section contributes 30%-40% of the pull-out force.

In terms of internal forces, the anchor reinforcement transmitted force to the bearing plate and later to the grouting body. The pressure experienced by the grouting body can be minimized with the existence of few bearing plates in delocalized arrangement that helps to increase the total area. Thus, this prevents the grouting from being crushed and causes partial damage.

② Strong applicability

The compressive stress-dispersive anchor has characteristics including fast construction speed and large pull out force bearing capacity. It is suitable for saturated clay, cohesive soil, sandy soil and so on. Besides, it can be widely used in engineering anchoring projects such as foundation pit support, counteracting uplift force structure construction, slope support. Statistical results from the previous construction projects: in saturated clay, c value is 20kpa, Φ value falls within the range 12°-14°, anchor pull-out force up to 600-900kN; in hard clay, the pull-out force further increased up to about 700-1100kN; in watery sandy soil, the anchor pull-out force reaches 600-1200kN.