- Home

- Custom Made

- Custom Manufacturing Power

1. Designing ability

Hot melt removable anchor, compressive stress-dispersive underreamed anchor by jet grouting and digital intelligent anchor are technologies developed by our own company. In addition, our company has the ability to design and carry out construction. We are familiar with the conditions, steps, requirements, and so on for on-site construction and these advantages have allowed us to adapt to the market better as we can provide our customer with the most appropriate product according to the customer’s actual needs.

Inventor Zhou Jianming said: "My love towards hot melt anchor is not sentimental. It is not easy to make a highly rational person born at the junction of Taurus and Gemini with A+ blood to express his love. Hot-melt anchors not only would meet all the requirements of permanent anchors, but also having digital intelligent to measure force, 4G transmission and so on just like the constellation in the sky that has room to rise. Only with the presence of all these factors my love towards it can be induced."

2. Design Principles(1). Compressive stress-dispersive underreamed anchor by jet grouting technology consists of prestressed ground anchor and prestressed jet grouting anchor.

The curing period of the compressive stress jet grouting anchor should longer than 14 days in cohesive soil and 10 days in sandy soil.

The curing period of the compressive stress ground anchor should longer than 20 days in cohesive soil and 14 days in sandy soil. It is applicable in plain land filling, cohesive soil, sandy soil, and partially weathered rock layers but not suitable in miscellaneous filling and moderately weathered rocks. When it is used in complex land layers consisting gravel clay, the pilot holes can be first introduced and conducts the integrated construction of rotary spray later.

(2). Prioritize the use of steel cofferdam when designing the hot melt removable anchor rod. When concrete cofferdams are used, as the steel strands are easily damaged during the construction as well as the process of tying the steel bars, therefore it is necessary to implement protective measures against the rods after the construction. Protect the case by planting it in the ground with depth at least 50cm and exceed the height of concrete capping beam 20cm and above. The height difference between the breast beam or the slurry wall anchor and the floor should be kept between 0.5 and 1.5 m. In addition, the distance between the front end of the anchor head and the underground outer wall should be more than 1.0m.

(3). The design of the bearing capacity of the anchor rod strictly refers to the bearing capacity of the test anchor. The height of the anchor hole should be higher than the elevation of the penetrating artesian pressure head. The actual setting of the specific elevation is in accordance to the condition of the test anchor.

Distance between adjacent anchoring sections should be longer than 2.0m, otherwise, adjust the distance between adjacent anchors 3° and above or stagger the adjacent anchoring sections for a distance of 5m long. Besides, make sure that the net distance of the expanding head anchorage section has length more than 1.5m, and at the same time, it is not suitable to be used in fluid-like clay soil or loose sand. The distance between the top of the anchorage section and the upper soft soil layer should not longer than 4.5m.

The materials used in the manufacturing process of the anchor are designated and purchased by NENGGONG while the subordinates from various factories perform the processing duties. Furthermore, we will conduct sampling inspection on the raw materials before allowing it to enter our main warehouse in a strict manner. This includes examination of its appearance, hardness and performance.

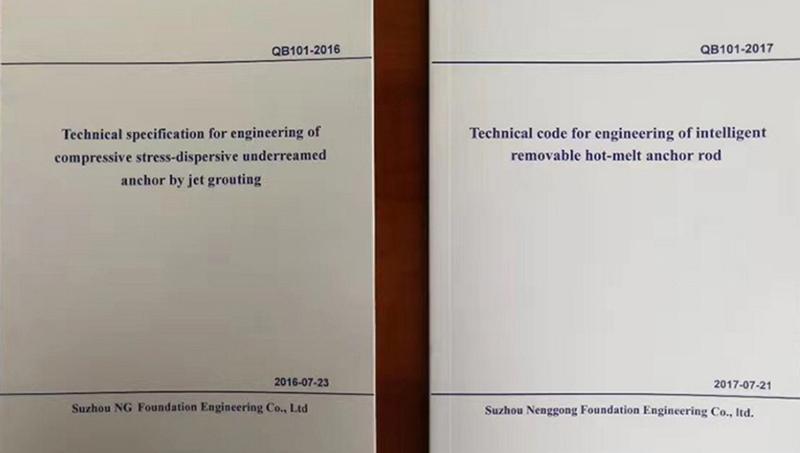

- We have our own technical systems and regulatory standards for our technical products which are higher than China's domestic norms.

- Our technical products had acquired a patent from European Union and Japan each.

- Our hot melt removable anchor product is able to meet the technical standard of permanent anchor.

Our products parts are manufactured in branch factories and assembled in the main factory later. Each of our product parts are purchased through market tendering and we have high demand on the quality of each components. The branch factories self-inspection of the products will provide a warranty for their products. Besides, we will conduct multiple examination including inspection of the products purchased before entering the main warehouse, sampling inspection of the parts before shipping out of factory, sampling inspection before the products entering the assembly line and performance testing after the completion of products assembly.

Unbonded steel strand

| Inspection standards | ISO 6934-4:1991, steel for the prestressing of concrete-Part 4: Strand, NEQ. Unbonded prestressing steel strand JG/T 161 |

| Inspection content | Mechanical properties of steel, tensile strength, bending strength, yield strength, elongation at break, anti-corrosion grease dropping point and so on. |

| Sampling standard | 60 tons / batc |

| Inspection standards | Enameled round aluminum winding wire - Part 5: Polyesterimide enameled round aluminum wire class 180 |

| Inspection content | Chemical properties, heat resistance, mechanical properties, unidirectional scratch resistance |

| Sampling standard | 3 meters / batch |

| Inspection standards | ISO 6934-4: 1991, steel for the prestressing of concrete-Part 4: Strand, NEQ. Unbonded prestressing steel strand JG/T 161 |

| Inspection content | Appearance, hardness |

| Sampling standard | 3% of each batch with 3 inspection groups and above |

| Inspection standards | ISO 6934-4: 1991, steel for the prestressing of concrete-Part 4: Strand, NEQ. Unbonded prestressing steel strand JG/T 161 |

| Inspection content | Appearance, hardness |

| Sampling standard | 3% of each batch with 3 inspection groups and above |

Hot melt anchor

| Inspection standards | Anchorage, grip and coupler for prestressing tendons GB/T 14370. Technical specification for application of anchorage grip and coupler for prestressing tendons JGJ85 |

| Inspection content | Static load anchoring performance, cyclic load performance, fatigue performance |

| Sampling standard | 3% of each batch with 3 inspection groups and above |

| Inspection standards | Plastics-Determination of tensile properties GB1040, bending test method for plastics GB1042, Plastics-Determination of Charpy impact properties-Part 1: non-instrumented impact test ISO 179-1: 2000, IDT, Plastics-Methods for determining the density of non-cellular plastics-Part 1: Immersion method, liquid pyknometer method and titration method ISO 1183-1:2004, IDT, Plastics-Determination of temperature of deflection under load-Part 1: General test method ISO 75-1:2003, IDT |

| Inspection content | Stretching, bending, impact properties, density, load deformation temperature |

| Sampling standard | 20 thousand each batch. Quantity: 3% |

(3) Inspection of manufacturing process (Self-inspection of production workers, inspection of each other works before handover, inspection by quality control crew, sampling inspection of end products. We conduct detailed examination in each sections, unqualified products are strictly prohibited)

Inspection of Hot melt anchor production project| Parts | Inspection Content | Quality Standard | Inspection Method |

| Quantity surveying of steel strand | Length deviation | ±20cm | Ruler |

| Plumpness of plastic accessories | Satisfy production and installation requirements without affecting its quality issues | Regular shape of plastic accessories | Visual inspection |

| Installation of anchor clips | Installation stress | Extrusion pressure 20MPa±2MPa | Examine the hydraulic pressure during the production |

| Reservation of anchor head clip steel strand | Reserved length | 1.0cm~2.0cm | Ruler |

| Hot melt anchor head | Plumpness | Plump injection molding | Visual inspection or static load test |

| Wiring | Secureness, secureness of heat-shrink tube | Pull and make sure no looseness. Secure it with heat-shrink tube and make sure no slipping. | Pull with hand, visual inspection |

| Hidden wire | Hidden wire | Secure hiding wire, no tangling and exposure | Visual inspection |

| Inspection of electrical conductivity | Resistor test | 3.5Ω-6Ω | Measure with multimeter |

Static load anchoring performance, cyclic load performance and fatigue performance will be conducted before shipping. Inspection standard satisfies anchorage, grip and coupler for prestressing tendons GB/T 14370.