- Home

- Products

- Temporary Strand Anchor

- RZ Series Temporary Removable Strand Anchor

RZ Series Temporary Removable Strand Anchor

The implementation of hot melt removable technology and automatic recovery equipment in the RZ series temporary removable strand anchor differentiates it from the YZ series permanent ground anchor. All tendons can be removed and recovered after the bracing work completed. Clearly, this helps to reduce the number of materials used and protect the soil at the same time providing a green construction environment for the adjacent underground space, effectively solving the problem of leftover tendon residue in the soil. Although the anchor mainly used in temporary bracing project, its static load anchoring performance, cyclic load performance and fatigue performance have equivalent quality as the permanent anchor. Automatic recovery equipment is required during the recovering process and it can be done by installing the anchor on the equipment and the steel strands will be removed automatically. This helps to avoid the safety issues if the recovering process conducted manually and the labor cost can be minimized.

Application- Foundation pit

- Temporary slope

- Counteracting uplift forces structure

- Fixation of bridge bearing platform

-

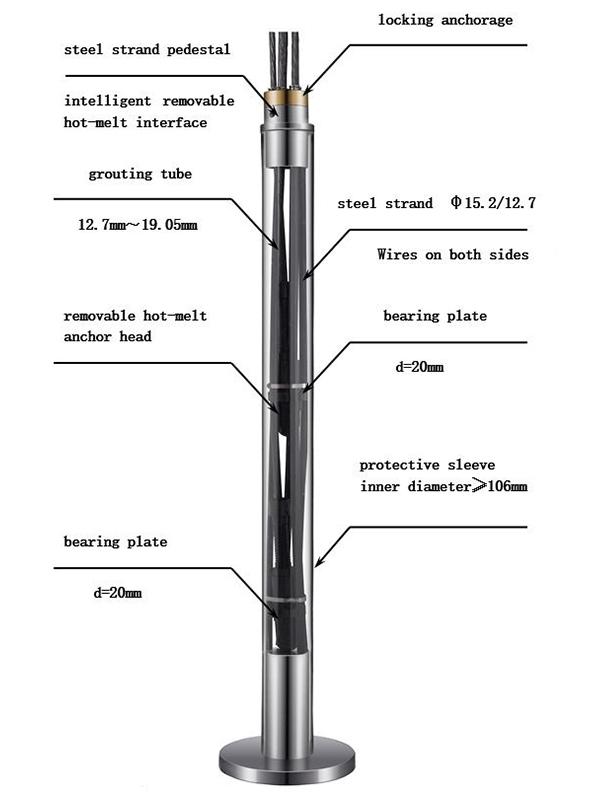

Parameters

- Construction process: Grouting at the casing

- Diameter of bearing plate: 100mm

- Thickness of bearing plate: 20mm

- Function type: Hot melt removable type

- Environmental friendly level: Environmental friendly PE, do not pollute the underground water

- Suitable steel strand type: Φ15.2/Φ12.7

- Be aware of the case model if casing is used: internal diameter more than 106mm

- Suitable grouting pipe: ½ inch- ¾ inch

-

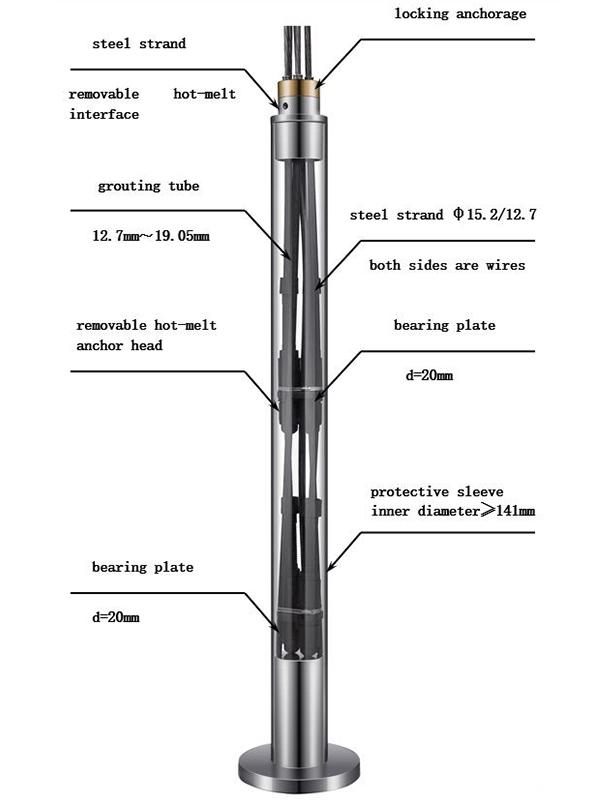

Parameters

- Construction process: Grouting at the casing

- Diameter of bearing plate: 112mm

- Thickness of bearing plate: 20mm

- Function type: Hot melt removable type

- Environmental friendly level: Environmental friendly PE, do not pollute the underground water

- Suitable steel strand type: Φ15.2/Φ12.7

- Be aware of the case model if casing is used: internal diameter more than 118mm

- Suitable grouting pipe: ½ inch- ¾ inch

-

Parameters

- Construction process: Grouting at the casing

- Diameter of bearing plate: 135mm

- Thickness of bearing plate: 20mm

- Function type: Hot melt removable type

- Environmental friendly level: Environmental friendly PE, do not pollute the underground water

- Suitable steel strand type: Φ15.2/Φ12.7

- Be aware of the case model if casing is used: internal diameter more than 141mm

- Suitable grouting pipe: ½ inch- ¾ inch

Features

- Removable anchor suitable for use in temporary construction project

- Allow multiple combinations and thus forming stress-dispersive structure

- Handled by SSPC-SP5 anti-corrosive treatment

- Three layers of anti-corrosive structure with all steel cores adopt the injection molding process, steel strands made from national standard unbonded steel strands and the connecting part embedded with sealing strip that expands upon contacting with water

Q1: How is the safety level of this product?

A: The static load coefficient of the hot melt removable anchor reached 96% which is nearly the same as the strength of steel strand. Besides, it satisfies the large fatigue test up to 2 million times and therefore it is applicable in permanent structure. It is rare for all the removable anchor in the world to meet this requirement.

Q2: How is the recovering speed?

A: With the use of fully automatic recovering equipment, taking 6 anchors with length 25 meters as an example, a group of 2 people in assembly line can complete the recovery of 90 anchors.

Q3: How much is the recovery rate of the anchor?

A: The rate is higher than 95% normally. Approaches can be made to realize 100% recovering rate.

Q4: How many cable structures can this product built up at most?

A: Using only this model, 5 cables can be built at most where the largest internal diameter of the anchor rod body is 100mm. If you wish to increase the quantity of the cable, please refer to the combination of grouting anchor.

Q5: What is compressive stress design?

A: Using only this model, 5 cables can be built at most where the largest internal diameter of the anchor rod body is 100mm. If you wish to increase the quantity of the cable, please refer to the combination of grouting anchor.

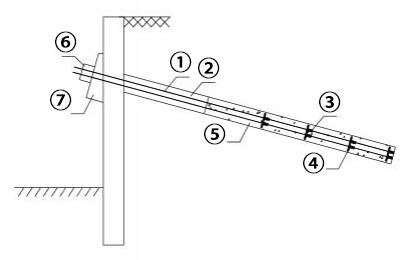

① Unbonded tendon with wire;

② Free segment;

③ Hot melt anchor;

④ Bearing plate;

⑤ Anchoring section;

⑥ Anchor;

⑦ Base plate

Suzhou NG Foundation Engineering Co., Ltd.

Add.: F3, No.711, Binhe Road, New District, Suzhou City, Jiangsu Province

Fax: +86-512-68093311

RZ-100 type removable anchor

RZ-100 type removable anchor RZ-112 type removable anchor

RZ-112 type removable anchor RZ-135 type removable anchor

RZ-135 type removable anchor