- Home

- Information

- What is Compressive Stress Design for Ground Anchor

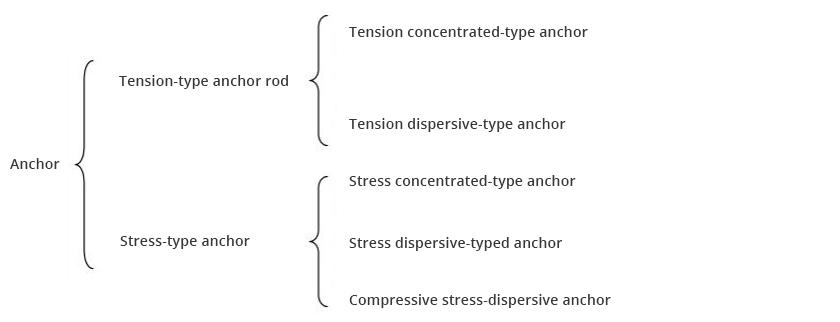

① Slip surface;

② Average length of unbonded segments;

③ Pulling force dispersion type;

④ Stress dispersion type;

⑤ Prestressed dispersion type

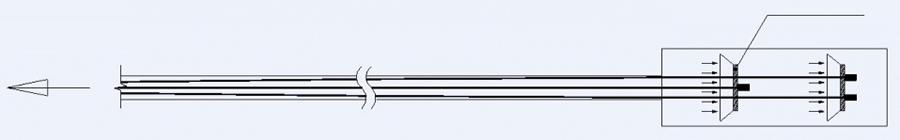

The compressive stress dispersive anchor composed of two or more bearing plates. The plates are uniformly distributed in the underreamed anchoring section of the anchor rod. The grout body is mounted on the drilling rod. The bearing plates are evenly placed at the anchoring section of the underreamed anchor by jet grouting. The plates have stress type anchor that behaves effectively as the dispersive underreamed anchoring section compressive stress under the effect of tensile load.

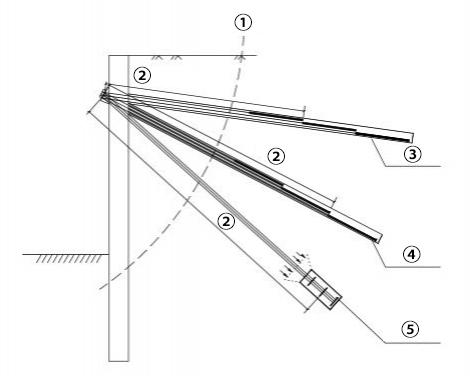

① Unbonded tendon with wire;

② Free segment;

③ Hot melt anchor;

④ Bearing plate;

⑤ Anchoring section;

⑥ Anchor;

⑦ Base plate

Compressive stress-dispersive anchor rod structure diagram

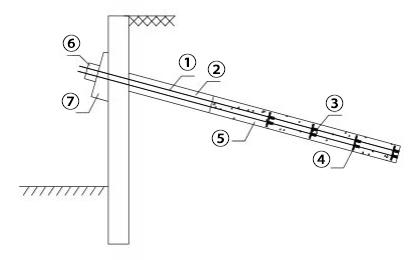

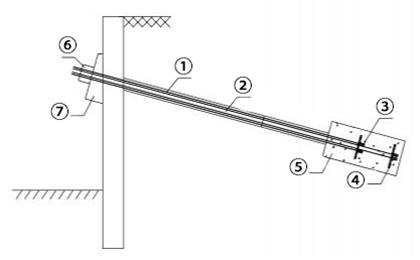

① Unbonded tendon with wire;

② Free segment;

③ Hot melt anchor;

④ Bearing plate;

⑤ Anchoring section;

⑥ Anchor;

⑦ Base plate

Compressive stress-dispersive anchor rod structure diagram

Advantage

① Reasonable structure

Ordinary tension-typed anchor first grouts the anchor end with cement mortar and the tensile force of the anchor is then transmitted to the cement mortar through the surrounding grip force of the anchor. Later, the force is transmitted to the reinforcement zone of the stable ground layer through the anchorage of the cement mortar and the frictional force between the ground layer. Tensile force is gradually transmitted from front to back to the anchoring soil. Shear stress along the rod has uneven distribution due to its centralized stress.

Compressive stress-dispersive anchor belongs to the pressure type anchor category. It uses unbonded steel strands to separate the reinforcement from the grout. The tensile stress of the rod is first transmitted to the grouting with the compressive stress which applied at the bottom end of the grouting by the bearing plate. Next, the force is transmitted to the stable soil body of the anchoring area through the end resistance between the bottom grouting body and the surrounding soil body.

Overall, the end bearing capacity of the soil and anchorage section provide a total of 60% to 70% of the pull-out force from the anchor while the side friction of the anchorage section contributes 30%-40% of the pull-out force.

In terms of internal forces, the anchor reinforcement transmitted force to the bearing plate and later to the grouting body. The pressure experienced by the grouting body can be minimized with the existence of few bearing plates in delocalized arrangement that helps to increase the total area. Thus, this prevents the grouting from being crushed and causes partial damage.

② Strong applicability

The compressive stress-dispersive anchor has characteristics including fast construction speed and large pull out force bearing capacity. It is suitable for saturated clay, cohesive soil, sandy soil and so on. Besides, it can be widely used in engineering anchoring projects such as foundation pit support, counteracting uplift force structure construction, slope support. Statistical results from the previous construction projects: in saturated clay, c value is 20kpa, Φ value falls within the range 12°-14°, anchor pull-out force up to 600-900kN; in hard clay, the pull-out force further increased up to about 700-1100kN; in watery sandy soil, the anchor pull-out force reaches 600-1200kN.